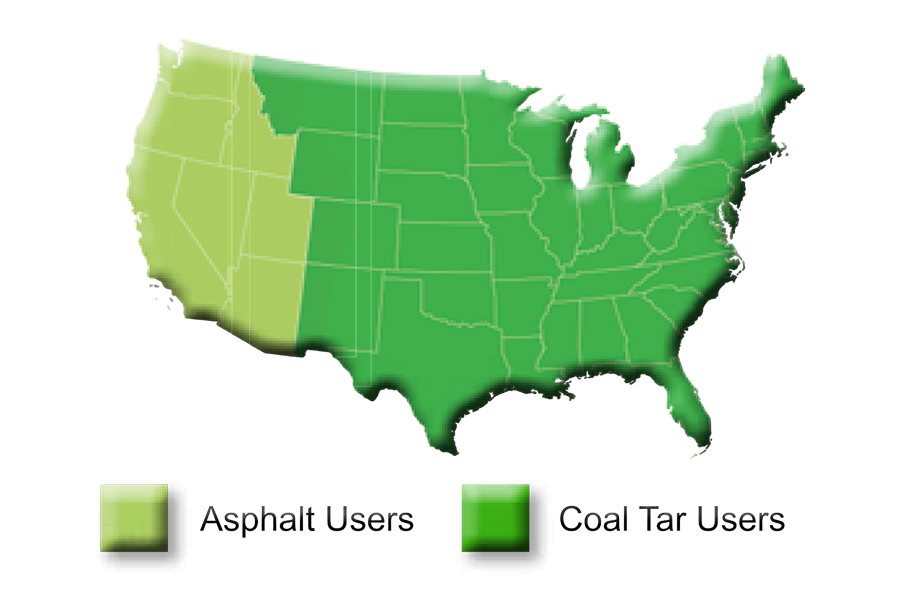

For decades, the sealcoating industry has been divided into two major camps – those who apply coal tar based sealers and those who apply asphalt based pavement sealers. Typically, contractors west of the Rocky Mountains have preferred asphalt based sealers, while those east of the Rockies preferred coal tar based sealers.

Before we discuss the merits of each type of sealer, a discussion of the chemical differences between coal tar pitch and petroleum asphalt will provide for a better understanding of the sealer differences.

Coal Tar Sealer

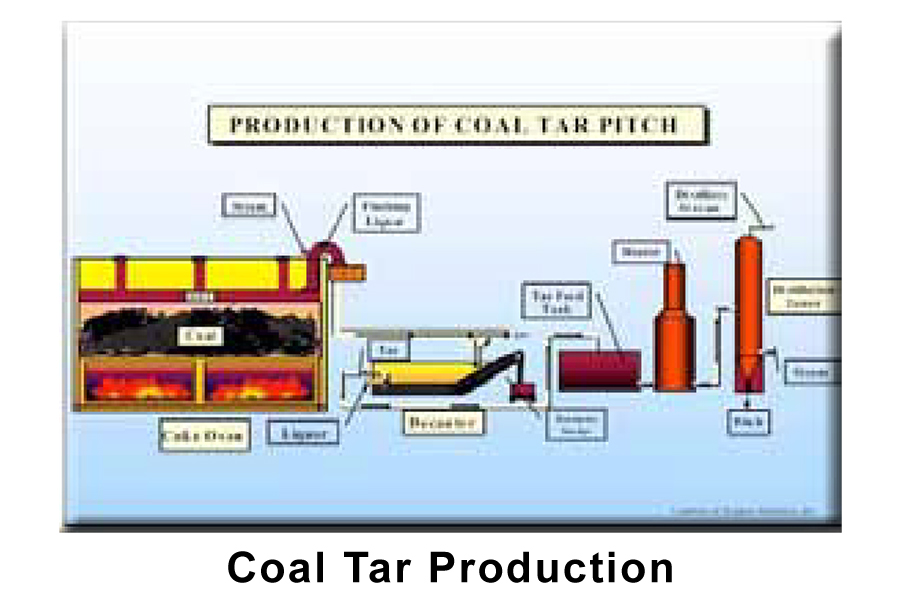

Crude Coal Tar is a by-product of converting coal to coke for use as a fuel for steel mills. The crude coal tar is further refined to produce RT-12 Coal Tar Pitch for use in pavement sealer production. The closed ring aromatic molecular structure of RT-12 coal provides good UV and chemical resistance.

Coal tar emulsion based sealer is the result of combining water, fillers and coal tar pitch to produce a water-based (emulsion) coal tar-based pavement sealcoating material.

Coal tar-based sealers have been actively promoted by sealcoat manufacturers east of the Rockies for decades. This has led the general use and acceptance of coal tar sealers by pavement sealcoating contractors. It’s what they’ve known and it’s what they are used to. Coal tar manufacturers have pointed to the added fuel resistance and overall durability of coal tar- based pavement sealers as the primary selling points.

Asphalt Based Sealer

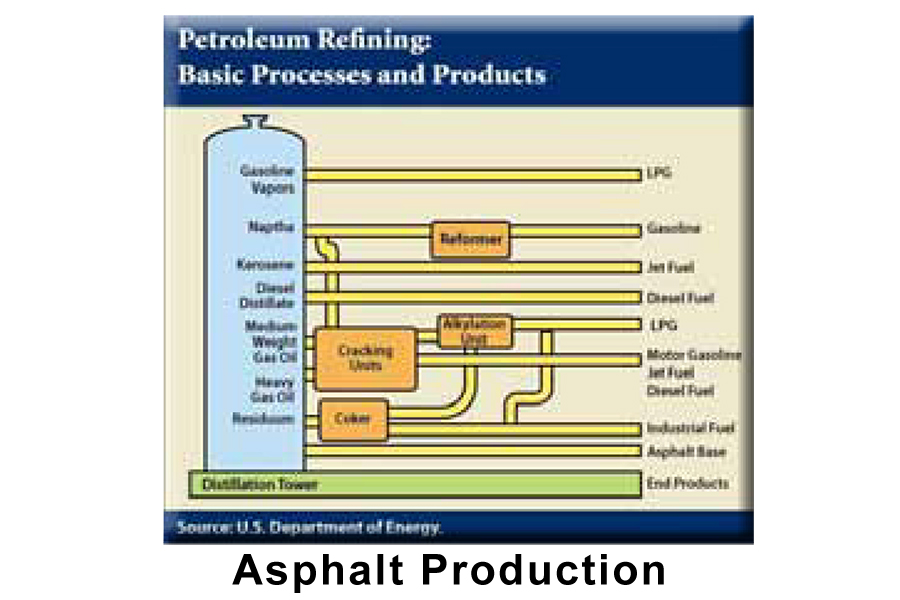

Petroleum Asphalt is a by-product of the oil refining process. Vacuum distillation separates asphalt from other components in crude oil (such as Naphtha, gasoline and diesel fuel). Asphalt is the sticky, black and highly viscous bitumen material that is used in the production of hot-mix and cold-mix blacktop as well as numerous asphalt based sealers, coating and waterproofing materials.Asphalt, water and fillers are combined to produce a water-based (emulsion) asphalt-based pavement sealcoating material.

West of the Rockies, asphalt-based sealers have been promoted by manufacturers and accepted by sealcoating contractors and property managers for decades. Producers have cited a more user-friendly material with no irritating fumes, blacker color and a more flexible product as key selling points. When formulated and applied correctly, asphalt- based sealers provide adequate fuel resistance and durability equal to and some cases superior to coal sealers.

In the past decade, asphalt based pavement sealers have made a dramatic pusheast into what has typically been referred to a “coal tar country”. Contractors and property owners alike have embraced the user-friendliness and blacker color of asphalt-based sealers.